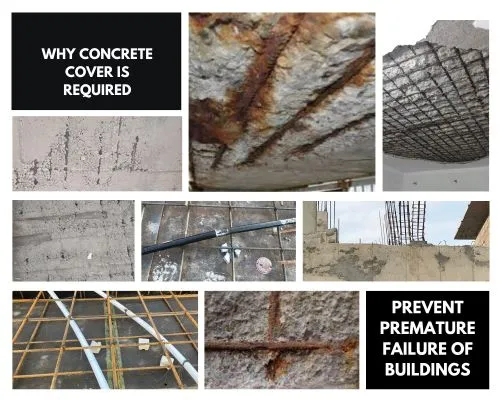

Concrete cover is a very crucial element. It’s not just another layer of concrete in a reinforced concrete structure. It is a crucial element that provides protection against corrosion, enhances fire resistance, increases durability, promotes good bond strength, prevents cracks, and contributes to overall structural performance. By understanding the significance of concrete cover and adhering to industry standards, we can ensure that our reinforced concrete structures stand the test of time, delivering safety and reliability for generations to come.

Corrosion Protection

One of the primary purposes of concrete cover is to protect the embedded steel reinforcement from corrosion. When steel is exposed to moisture and oxygen, it can corrode, leading to a reduction in its strength and durability. Concrete cover acts as a barrier, preventing moisture and oxygen from reaching the steel and thereby inhibiting corrosion.

Fire Resistance

Concrete cover provides a layer of protection against fire. Concrete has a high fire resistance compared to steel, so the cover helps to shield the steel reinforcement from the effects of heat during a fire. This is crucial for maintaining the structural integrity of the building in case of a fire.

Durability

The concrete cover helps to protect the reinforcement from environmental factors such as freeze-thaw cycles, chemical exposure, and abrasion, which can degrade the steel over time. This ensures the long-term durability of the structure.

Bond Strength

Adequate concrete cover also plays a role in ensuring good bond strength between the concrete and the reinforcement. It allows the concrete to properly grip the steel bars, transferring stresses and loads effectively between the two materials.

Preventing Cracks

Concrete cover can help to prevent or control cracking in the concrete due to shrinkage, temperature variations, and other factors. This is important for maintaining the structural integrity and aesthetics of the structure.

Structural Performance

The thickness of the concrete cover is often specified in structural design to provide the necessary protection and to ensure that the reinforcement can carry the required loads and stresses without reaching its yield strength.

Code Requirements

Building codes and standards set minimum concrete cover requirements. These requirements take into account factors such as the type of structure, environmental exposure conditions, and the size of the reinforcement. Compliance with these standards is essential to guarantee the safety and performance of the structure.

How much cover is required as per IS 456?

As per Indian building code IS 456 the cover required is as following:-

- Slab = 20mm

- Beam = 25mm

- Column = 40mm

- Footing = 50mm

How can we provide concrete cover in RCC ?

As per building codes spacers or cover blocks needs to be provided to form a gap between steel bars and shuttering. This gap is subsequently filled by casting of concrete. These spacers or cover blocks can be made from concrete or plastic.

Does building codes allow use of plastic in RCC ?

Yes. Building codes do allow use of plastic as spacer in RCC. As per IS 456 : 2000, section 12.3.2 the “Spacers, cover blocks should be of concrete of same strength or PVC”. But it does not talk about requirements for plastic spacer. As per BS 7973 if material is non cementious than at least 25% area under it’s periphery should be void. This is to ensure proper bonding of spacer and concrete and spacer becomes part of concrete. Heavy duty spacers should are those which can take load of more than 3 Kn.

What type of cover block should be use ?

Job of a spacer or cover block is to raise reinforcement from shuttering. But if gets displacement from it’s position than it is of no use. Any reduction of cover from any point due to breakage or displacement of cover block can be determinental to overall corrosion resistance, strength, safety and durability of construction. So it is important to choose a cover block which can ensure 100% fixity, can withstand stresses of onsite conditions and meet requirements of building codes.

Which spacer or cover block ensure 100% fixity and meet requirements of codes ?

Cross lock spacers and rebar chairs have a in build self locking system to ensure 100% fixity. They have got a hollow structure for concrete to flow through it. Also they are designed to meet specific requirements of different elements of RCC such as slab, beam, column, footing, concrete wall, cantilevers, electrical pipes etc.

How to calculate cover block quantity in RCC ?

This will depend upon spacing distance and design of reinforcement. As per IS 456 distance between two spacers should be 1 meter, but the closer spacing may be required. But for practical purposes greater elaborations may be required. Cross lock page guides about how their different products designed for different elements of RCC should be used and in how much quantity they shall be required.